Production specifications

Melting shop

Pair of cold weather cupolas with an inner diameter of 700 mm and maximum production of liquid metal about 2.5 t / hour.

Ladles 800 kg of liquid metal.

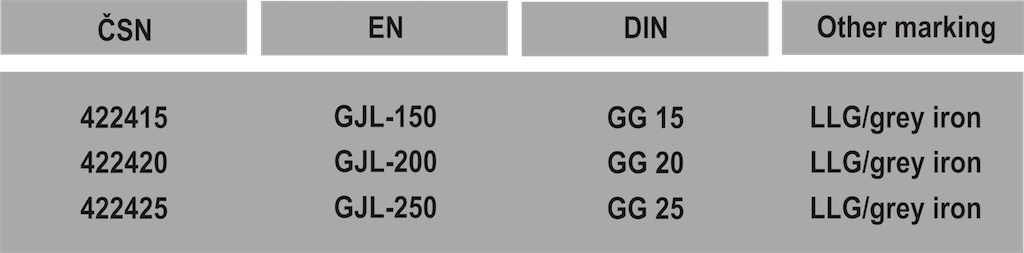

Materials

Molding shop

Moulding sand with bentonite binder.

Machine moulding

The weight of manufactured castings from cca 0,1 kg up to cca 90 kg.

Jolt-squeeze moulding machine FOROMAT 20

- 2 couples moulding machines

- Frame dimensions up to 550×550 mm

Jolt-squeeze moulding machine FOROMAT 30

- 1 couple moulding machines

- Frame dimensions up to 750×750 mm

Hand moulding

The weight of manufactured castings from caa 350 kg.

Core shop

Manufacturing cores manually or on two core shooters.

Cleanning shop

We blast castings on 2 chain shot-blasting machines, rotary fettling table and chamber hanging blasting machine. Finishing on desk grinders or manually in fitting cabinets.

Pattern shop

Production of models, machining and painting of castings.

Testing and quality inspection

The material quality control is done spectral analysis, measurement of hardenss HB and, if required by customer, we verify the strength of materiál by tensile test